What we offer

We specialise in diagnostic service, repair and supply of Industrial Electronic Equipment throughout New Zealand.

Our key areas of expertise are the repair and service of Variable Speed Drives (VSDs), Computer Controllers (CNC) and related gear.

Sub-categories include Motors and Encoders, Programmable Logic Controllers (PLC’s), Human-Machine Interfaces (HMI’s) etc.

Industries

We specialise in diagnostic service, repair and supply of Industrial Electronic Equipment throughout New Zealand.

Our key areas of expertise are the repair and service of Variable Speed Drives (VSDs), Computer Controllers (CNC) and related gear. Sub-categories include Motors and Encoders, Programmable Logic Controllers (PLC’s), Human-Machine Interfaces (HMI’s) etc.

APPAREL

We are the New Zealand specialists for industrial electronic equipment used to work with fabrics.

AVIATION SUPPORT

We have experience in repairing and servicing flight simulators and deck controllers .

BUILDING & CABINETRY

We are industry specialists for electronic equipment used for cabinet making. e.g. CNC machinery.

CRANES

We are the New Zealand specialists for industrial electronic equipment used to work with fabrics.

ELECTRICAL

Here at Attwood Electronics, we partner with Industrial Electricians to be your electronics division.

ENGINEERING

We are industry specialists for electronic equipment used in engineering. e.g. CNC machinery.

FOOD & BEVERAGE

Electronic issues in food and beverage production lines can result in significant downtimes.

PHARMACEUTICAL

Experts are needed to fix the electronics in this cutting-edge machinery that are constantly.

PLASTIC MOULDING

We are specialists in the Machine Control Systems that are used in the plastic industry.

PRINTING & PACKAGING

We are specialize in servicing and repairing motor drive or servo motor, computer controller.

UTILITIES & INFRASTRUCTURE

We have experience with the electronic equipment used in the systems.

services

Welcome to Attwood Electronics. We specialise in servicing and supplying Industrial Electronic Equipment throughout New Zealand. Our core specialty is in Motor Drive Equipment and Machine Control Systems. We strive for quality and integrity in all we do.

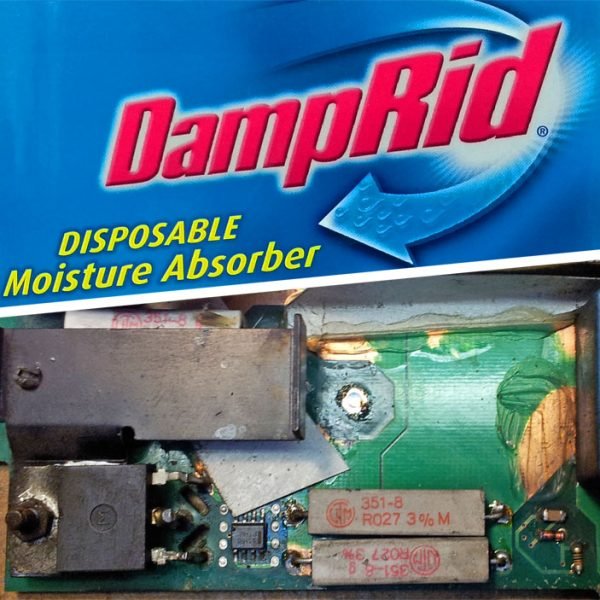

Industrial Electronics Servicing & Repairing

With a team of professional and highly experienced electronic engineers at Atwood Electronics.

Supplying Electronic Equipment

Our engineers have become adept at sourcing new and refurbished equipment from our extensive global supply network.

Designs & Projects

Attwood Electronics offers assistance with machine development and automation. We have the ability to design and produce electronic circuits etc.

Machine Electronic Maintenance

Most machine user-manuals contain detailed instructions about maintenance. For a machine to have a long productive life.

what industries

we are involved with

Cabinet Making

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Electrical

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Engineering

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Plastics

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Apparel

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

What our clients say

Hi Wayne, Thanks for your prompt support and help with this. Keep us posted on how we go for the best solution for the repairs.

Meet the Team

Wayne Handisides

Electronic Engineer / Managing Director

Denise Handisides

Office Manager / Director

Micah Fleming

Electronic Engineering Student

Steve Lacey

Electronic Engineer / Technical Manager